Capillary Bonding Capillary Ceramic Airson pacadh semiconductor

Iarrtas toraidh

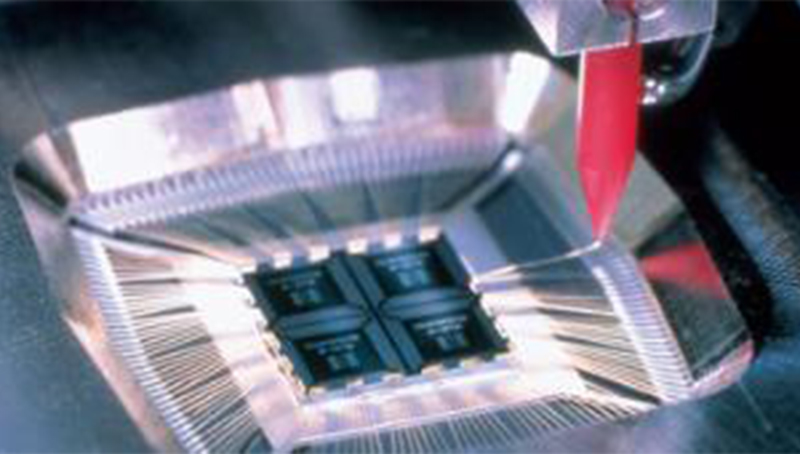

Is e inneal ceirmeag axisymmetric a th’ ann an Ceramic Capillary le tuill anns an t-slighe dhìreach, a bhuineas do cho-phàirt ceirmeag meanbh-structar ceart.A thaobh tagradh, tha an Ceramic Capillary air a chleachdadh mar inneal ceangail uèir anns a ’phròiseas ceangail uèir.Faodaidh WireBonding an luaidhe meatailt a dhèanamh tàthadh gu dlùth leis a’ phloc substrate le bhith a’ cleachdadh uèirichean meatailt tana (copar, òr, msaa) agus teas, cuideam, agus lùth ultrasonic, gus an eadar-cheangal dealain eadar sgoltagan agus substrates a thoirt gu buil agus an iomlaid fiosrachaidh eadar sgoltagan.Freagarrach airson ceangal agus pacadh SCR, SAW, LED, diode, triode, chip IC agus cuairtean eile.

Buannachdan toraidh

OPT Gearradh Innealan Co., LTD.Tha e suidhichte ann an Shenzhen, Guangdong, Sìona.Is e companaidh a th’ ann a tha ag amalachadh cinneasachadh, reic, rannsachadh agus leasachadh.Agus is urrainn dhaibh dealbhadh agus saothrachadh dhealbhan, stuthan agus innealan neo-àbhaisteach a ghabhail os làimh.Gabh gu daingeann ri stuthan cinneasachaidh dachaigheil den chiad loidhne gus dèanamh cinnteach à seasmhachd diofar bhuilleagan de stuthan.Smachd teann air a’ phròiseas toraidh gus dèanamh cinnteach à càileachd innealan.Tha neart teignigeach mòr aig a’ chompanaidh, comas cinneasachaidh làidir, riaghladh saidheansail, leis an adhbhar “mairsinn le càileachd, leasachadh le cliù”, agus an-còmhnaidh a’ togail air adhart gus toraidhean nas fheàrr a thoirt do luchd-ceannach.

Lìbhrigeadh ceart, seirbheis mhath

1. Tha an siostam riochdachaidh, saothrachaidh agus còmhdhail iomlan fhèin aig OPT Cutting Tools.Air lìbhrigeadh ùine.

2. Faodar conaltradh agus iomlaid aon ri aon a dhèanamh le luchd-ceannach gus innealan ceangail Ceramic nas freagarraiche agus nas fheàrr a thoirt do luchd-ceannach

3. Gnàthaich paramadairean sònraichte a rèir riatanasan sònraichte luchd-ceannach;

Ùrachadh luath air ìre Bonding Capillary Material

Air bunait alùmanum ogsaid tùsail, tha zirconia, cromium oxide, msaa air an cur ris gus structar moileciuil an Capillary Ceramic a dhèanamh nas toinnte, le cruas nas àirde, caitheamh caitheamh nas fheàrr agus beatha seirbheis nas fhaide.Lùghdaich amannan caitheamh agus ath-nuadhachadh tip cleaver ceirmeag rè tàthadh uèir.

Dingean ceangail uèir tana Meud ceart

Bidh a’ chompanaidh againn a’ gabhail ri seata iomlan de uidheamachd cinneasachaidh a chaidh a thoirt a-steach gus gach meud àbhaisteach a phròiseasadh.Bidh uidheamachd giullachd àrd mionaideachd agus eòlas giollachd beairteach a ’toirt toraidhean meud teann do luchd-ceannach.

Àrd mionaideachd, mionaideachd àrd meud, nas lugha machining agus uachdar rèidh.

Tha cruinneas àrd aig an toradh, mionaideachd àrd meud, nas lugha de mheud innealachaidh agus uachdar rèidh.

Tha structar an Ceramic Capillary gu math mionaideach agus iom-fhillte, agus tha na prìomh tomhasan aige a 'toirt buaidh mhòr air a' bhuaidh ceangail uèir.Bidh Innealan Gearraidh OPT a 'cumail smachd teann air a' phròiseas riochdachaidh gus dèanamh cinnteach à càileachd innealan.Gus cruinneas toraidh àrd a choileanadh, mionaideachd àrd meud, nas lugha de innealachadh, agus uachdar rèidh.Tha a’ chompanaidh againn dealasach a thaobh R&D agus cinneasachadh innealan ceangail ceirmeag dachaigheil meadhanach agus àrd ann an raon pacaidh IC.Tha pùdar ceirmeach agus pàirtean embryo air an leasachadh gu tur agus air an dèanamh gu neo-eisimeileach.

![]()

BPP: 150 μm (μm/mil)

| Pàirt NO. | WD | H | T | CD | OR | α | Θ | CA |

| A-1 | 38/1.5 | 51/2.0 | 229/9.0 | 102/4.0 | 38/1.5 | 8° | 30° | 120° |

| A-2 | 38/1.5 | 51/2.0 | 152/6.0 | 66/2.6 | 10/0.4 | 0° | 30° | 90° |

| A-3 | 38/1.5 | 51/2.0 | 229/9.0 | 86/3.4 | 102/4.0 | 0° | 30° | 90° |

| A-4 | 38/1.5 | 51/2.0 | 203/8.0 | 86/3.4 | 61/2.4 | 0° | 30° | 90′ |

| A-5 | 38/1.5 | 56/2.2 | 239/9.4 | 102/4.0 | 38/1.5 | 8° | 30° | 120° |

| A-6 | 38/1.5 | 56/2.2 | 229/9.0 | 96/3.8 | 102/4.0 | 0° | 30° | 90° |

| A-7 | 38/1.5 | 56/2.2 | 203/8.0 | 86/3.4 | 61/2.4 | 0° | 30° | 90° |

| A-8 | 38/1.5 | 64/2.5 | 239/9.4 | 102/4.0 | 38/1.5 | 6° | 30° | 120° |

| A-9 | 38/1.5 | 64/2.5 | 203/8.0 | 89/3.5 | 61/2.4 | 0° | 30° | 90° |

| A-10 | 51/2.0 | 64/2.5 | 191/7.5 | 81/3.2 | B/0.3 | 0° | 30° | 90° |

| A-11 | 51/2.0 | 64/2.5 | 292/11.5 | 102/4.0 | 127/5.0 | 0° | 30° | 90° |

| A-12 | 51/2.0 | 76/3.0 | 356/14.0 | 122/4.8 | 152/6.0 | 0° | 30° | 90° |

| A-13 | 51/2.0 | 89/3.5 | 419/16.5 | 135/5.3 | 178/7.0 | 0° | 30° | 90° |

| A-14 | 51.64/2.0.2.5 | 76/3.0 | 330/13.0 | 140/5.5 | 64/2.5 | 8° | 30° | 120° |

| A-15 | 64.76/2.5.3.0 | 89/3.5 | 330/13.0 | 127/5.0 | 64/2.5 | 8° | 30° | 120° |

| A-16 | 64.76/2.5.3.0 | 102/4.0 | 330/13.0 | 140/5.5 | 64/2.5 | 8° | 30° | 120° |

| A-17 | 76/3.0 | 102/4.0 | 483/19.0 | 168/6.6 | 203/8.0 | 0° | 30° | 90° |

BPP: 140 μm (μm/mil)

| Pàirt NO. | WD | H | T | CD | OR | α | Θ | CA |

| B-1 | 22/0.9 | 33/1.3 | 140/5.5 | 64/2.5 | 20/0.8 | 8° | 30° | 120° |

| B-2 | 25/1.0 | 38/1.5 | 165/6.5 | 74/2.9 | 25/1.0 | 8° | 30° | 120° |

| B-3 | 25/1.0 | 38/1.5 | 89/3.5 | 53/2.1 | B/0.3 | 0° | 30° | 90° |

| B-4 | 25/1.0 | 38/1.5 | 114/4.5 | 53/2.1 | 8/0.3 | 0° | 30° | 90° |

| B-5 | 25/1.0 | 38/1.5 | 178/7.0 | 64/2.5 | 76/3.0 | 0° | 30° | 90° |

| B-6 | 25/1.0 | 38/1.5 | 203/8.0 | 53/2.1 | 89/3.5 | 0° | 30° | 90° |

| B-7 | 25/1.0 | 43/1.7 | 165/6.5 | 74/2.9 | 25/1.0 | 8° | 30° | 120° |

| B-8 | 25/1.0 | 43/1.7 | 203/8.0 | 53/2.1 | 89/3.5 | 0° | 30° | 90° |

| B-9 | 25.30/1.0.1.2 | 43/1.7 | 229/9.0 | 74/2.9 | 30/1.2 | 8° | 30° | 120° |

| B-10 | 25.30/1.0.1.2 | 43/1.7 | 152/6.0 | 59/2.3 | B/0.3 | 8° | 30° | 120° |

| B-11 | 25.30/1.0.1.2 | 43/1.7 | 203/8.0 | 74/2.9 | 89/3.5 | 0° | 30° | 90° |

| B-12 | 25.30/1.0.1.2 | 46/1.8 | 229/9.0 | 74/2.9 | 38/1.5 | 8° | 30° | 120° |

| B-13 | 30/1.2 | 46/1.8 | 203/8.0 | 76/3.0 | 89/3.5 | 0° | 30° | 90° |

BPP: 100m(μm/m)

| Pàirt NO. | WD | H | T | CD | OR | α | Θ | CA |

| C-1 | 25/1.0 | 38/1.5 | 130/5.1 | 53/2.1 | 30/1.2 | 11 | 30° | 90° |

| C-2 | 30/1.2 | 38/1.5 | 130/5.1 | 56/2.2 | 30/1.2 | 11 | 30° | 90° |

| C-3 | 30/1.2 | 38/1.5 | 130/5.1 | 56/2.2 | 30/1.2 | 8′ | 30° | 90° |

| C-4 | 30/1.2 | 38/1.5 | 130/5.1 | 56/2.2 | 30/1.2 | 4′ | 30° | 90° |

| C-5 | 30/1.2 | 41/1.6 | 130/5.1 | 59/2.3 | 30/1.2 | 11 | 30° | 90° |

BPP: 90m(μm/m)

| Pàirt NO. | WD | H | T | CD | OR | α | Θ | CA |

| D-1 | 25/1.0 | 33/1.3 | 109/4.3 | 51/2.0 | 13/0.5 | 11° | 30° | 90° |

| D-2 | 25/1.0 | 33/1.3 | 109/4.3 | 51/2.0 | 13/0.5 | 8° | 30° | 90° |

| D-3 | 25/1.0 | 33/1.3 | 109/4.3 | 51/2.0 | 13/0.5 | 4° | 30° | 90° |

| D-4 | 25/1.0 | 35/1.4 | 109/4.3 | 51/2.0 | 20/0.8 | 11° | 30° | 90° |

| D-5 | 30/1.2 | 38/1.5 | 109/4.3 | 51/2.0 | 20/0.8 | 11° | 30° | 90° |

| D-6 | 30/1.2 | 38/1.5 | 109/4.3 | 53/2.1 | 1310.5 | 8° | 30° | 90° |

| D-7 | 30/1.2 | 38/1.5 | 109/4.3 | 53/2.1 | 13/0.5 | 4° | 30° | 90° |

BPP: 80 m(μm/m)

| Pàirt NO. | WD | H | T | CD | OR | α | Θ | CA |

| E-1 | 25/1.0 | 33/1.3 | 99/3.9 | 48/1.9 | 13/0.5 | 4° | 30° | 90° |

| E-2 | 25/1.0 | 33/1.3 | 99/3.9 | 4B/1.9 | 13/0.5 | 8° | 30° | 90° |

| E-3 | 25/1.0 | 33/1.3 | 99/3.9 | 48/1.9 | 13/0.5 | 11° | 30° | 90° |

| E-4 | 25/1.0 | 35/1.4 | 99/3.9 | 46/1.8 | 13/0.5 | 11° | 30° | 90° |

| E-5 | 30/1.2 | 38/1.5 | 99/3.9 | 51/2.0 | 13/0.5 | 4° | 30° | 90° |

| E-6 | 30/1.2 | 3B/1.5 | 99/3.9 | 51/2.0 | 13/0.5 | 8° | 30° | 90° |

BPP: 70m(μm/m)

| Pàirt NO. | WD | H | T | CD | OR | α | Φ | CA |

| F-1 | 25/1.0 | 30/1.2 | 91/3.6 | 43/1.7 | 10/0.4 | 8° | 30° | 90° |

| F-2 | 25/1.0 | 30/1.2 | 91/3.6 | 43/1.7 | 10/0.4 | 4° | 30′ | 90° |

| F-3 | 25/1.0 | 33/1.3 | 91/3.6 | 43/1.7 | 13/0.5 | 11° | 30′ | 90° |

BPP: 60 m(μm/m)

| Pàirt NO. | WD | H | T | CD | OR | α | Φ | CA |

| G-1 | 23/0.9 | 28/1.1 | 81/3.2 | 35/1.4 | 13/0.5 | 11° | 30° | 90° |

| G-2 | 25/1.0 | 30/1.2 | 81/3.2 | 35/1.4 | 13/0.5 | 11° | 30° | 90° |